Trying to narrow down oil leaks

-

k. rogers

- Posts: 480

- Joined: Thu Feb 23, 2006 9:43 pm

- Your interest in the forum: 1933 7hp Kingfisher

1935 7hp Weasel

1928 7hp Sports replica

1952 Bradford special - Given Name: Ken

- Location: Cornwall

Re: Trying to narrow down oil leaks

You have probably just altered the ignition timing. It's so easily done during this process as the spigot only needs to move slightly from its position to put it out. Check to see when it is firing using whatever method you like to use. I do mine by taking a spark plug out and using a stick down into the cylinder to feel when the cylinder is at the top. If you take the distributor cap off you should here the spark and you can turn the distributor either way until it sparks at TDC (or immediately after - never before!). Isn't the nob you mention just the oiler for the distributor?

7hp Weasel & Kingfisher

-

ChrisE

- Posts: 82

- Joined: Sat Sep 01, 2018 8:23 am

- Your interest in the forum: Have a 1929 Full Four

- Given Name: Chris

Re: Trying to narrow down oil leaks

All sounds a bit daunting but i can try.

Presumably I can take the plugs out and rest them on the side.

Turn over the starting handle until one side plug sparks/clicks

Slacken off the clamp (that I have already just tightened!)

Turn the engine with the handle until the piston (that I can see through the plug hole) is just beyond TDC

Retighten the clamp

This way I don’t have to touch the distributor.

Chris

Presumably I can take the plugs out and rest them on the side.

Turn over the starting handle until one side plug sparks/clicks

Slacken off the clamp (that I have already just tightened!)

Turn the engine with the handle until the piston (that I can see through the plug hole) is just beyond TDC

Retighten the clamp

This way I don’t have to touch the distributor.

Chris

-

k. rogers

- Posts: 480

- Joined: Thu Feb 23, 2006 9:43 pm

- Your interest in the forum: 1933 7hp Kingfisher

1935 7hp Weasel

1928 7hp Sports replica

1952 Bradford special - Given Name: Ken

- Location: Cornwall

Re: Trying to narrow down oil leaks

Hi Chris,

It may be easier to simply turn the Distributor one way or the other until the points spark at (or just after) top dead centre - that's how you would normally set the timing, anyway. It will be much easier and I really mean it may only be out by about 10 degrees.

It may be easier to simply turn the Distributor one way or the other until the points spark at (or just after) top dead centre - that's how you would normally set the timing, anyway. It will be much easier and I really mean it may only be out by about 10 degrees.

7hp Weasel & Kingfisher

-

ChrisE

- Posts: 82

- Joined: Sat Sep 01, 2018 8:23 am

- Your interest in the forum: Have a 1929 Full Four

- Given Name: Chris

Re: Trying to narrow down oil leaks

Well, good news and bad news.

I did the timing. That was actually extremely simple. I took the plug out, watched the 4 stroke exhaust/intake/compression/fire on one side by watching the valves open/close then when worked out what was the top of the piston just at ‘fire, I could see the piston through the plug hole and went to set the points. The distributor doesn’t move at all. The retaining bolt goes through a hole so even when slackened it will not rotate. Instead I slackened the clamp on the timing shaft and turned that til the points just broke-contact. The engine starts and runs perfectly.

Unfortunately though the oil leak is just as bad as ever. I am wondering what to do next? The clamp is hard against the brass bush so there is no end float in the shaft. There does seem to be oil coming out of the flywheel end as if there is excessive crankcase pressure but the breather valve seems to be fine so I’m sure it’s not.

Lost again!

Chris

I did the timing. That was actually extremely simple. I took the plug out, watched the 4 stroke exhaust/intake/compression/fire on one side by watching the valves open/close then when worked out what was the top of the piston just at ‘fire, I could see the piston through the plug hole and went to set the points. The distributor doesn’t move at all. The retaining bolt goes through a hole so even when slackened it will not rotate. Instead I slackened the clamp on the timing shaft and turned that til the points just broke-contact. The engine starts and runs perfectly.

Unfortunately though the oil leak is just as bad as ever. I am wondering what to do next? The clamp is hard against the brass bush so there is no end float in the shaft. There does seem to be oil coming out of the flywheel end as if there is excessive crankcase pressure but the breather valve seems to be fine so I’m sure it’s not.

Lost again!

Chris

-

Tony Fearn

- Posts: 1743

- Joined: Thu Feb 09, 2006 5:33 pm

- Your interest in the forum: Early pre-wars. Owner of 1933 'Flying Fox' 'Sarah Jane, and 1934 Short saloon 'Mary Ellen'.

- Given Name: Anthony

- Location: Clayton le Moors, Lancashire, the Premier County in the British Isles!!

Re: Trying to narrow down oil leaks

Hi Chris,

Have a look at this:-

viewtopic.php?f=4&t=1315&hilit=redex

It's in the Pre-war section some time ago.

Tony.

Have a look at this:-

viewtopic.php?f=4&t=1315&hilit=redex

It's in the Pre-war section some time ago.

Tony.

-

ChrisE

- Posts: 82

- Joined: Sat Sep 01, 2018 8:23 am

- Your interest in the forum: Have a 1929 Full Four

- Given Name: Chris

Re: Trying to narrow down oil leaks

Thanks Tony I read that,

I might have solved some at least of the problem. It seems the breather valve, and keeping a correct air pressure within the crankcase is key to so much on this engine!

I messed about with the leather flap valve in the breather which for us isn’t too easy. A previous owner has (for some reason) drilled out all the holes so making a flap very difficult. I would be really keen to know what the inside of a breather flap valve should look like. Anyway, onece messed about with I went out for a 20+ mile run and the oil leaks were much better. Then I tested the pressure in the crankcase with an (engine) oil filled home made manometer. See attached photos. It didn’t seem to vary too much between tickover and fast reving.

In 20+ miles it has used (or thrown out) 10mm of oil on the dipstick. Some improvement.

As you can see the pressure is 480mm of engine oil. Does anyone know how low I should, can, get it to be?

Chris

I might have solved some at least of the problem. It seems the breather valve, and keeping a correct air pressure within the crankcase is key to so much on this engine!

I messed about with the leather flap valve in the breather which for us isn’t too easy. A previous owner has (for some reason) drilled out all the holes so making a flap very difficult. I would be really keen to know what the inside of a breather flap valve should look like. Anyway, onece messed about with I went out for a 20+ mile run and the oil leaks were much better. Then I tested the pressure in the crankcase with an (engine) oil filled home made manometer. See attached photos. It didn’t seem to vary too much between tickover and fast reving.

In 20+ miles it has used (or thrown out) 10mm of oil on the dipstick. Some improvement.

As you can see the pressure is 480mm of engine oil. Does anyone know how low I should, can, get it to be?

Chris

-

ChrisE

- Posts: 82

- Joined: Sat Sep 01, 2018 8:23 am

- Your interest in the forum: Have a 1929 Full Four

- Given Name: Chris

Re: Trying to narrow down oil leaks

Video

https://www.veoh.com/watch/v1419477082scZwdrN

Sorry about the rotation! click on the full size button too

Chris

https://www.veoh.com/watch/v1419477082scZwdrN

Sorry about the rotation! click on the full size button too

Chris

-

Keith Clements

- websitedesign

- Posts: 3968

- Joined: Wed Feb 08, 2006 11:22 am

- Your interest in the forum: Jup NKD 258, the most widely travelled , raced and rallied Jowett.

- Given Name: Keith

- Contact:

Re: Trying to narrow down oil leaks

Is that negative pressure or positive? Most engines require some suction to purge exhaust gasses from the crankcase.

skype = keithaclements ;

-

David Morris

- Posts: 837

- Joined: Thu Feb 09, 2006 9:23 am

- Your interest in the forum: Jowett Javelins since 1964. Now a Jowett Stationary engine owner and club member since 1964.

- Given Name: David

- Location: Sunny Bristol

Re: Trying to narrow down oil leaks

Sorry I cannot help with the technical info, but they are very good photos! Well done!

David

David

-

ChrisE

- Posts: 82

- Joined: Sat Sep 01, 2018 8:23 am

- Your interest in the forum: Have a 1929 Full Four

- Given Name: Chris

Re: Trying to narrow down oil leaks

The pressure is positive pressure. It would be great if I can find a way to reduce the pressure.

I'd be really interested if someone with a similar engine can measure their pressure too?

I have so many photos. I need to know how to load them onto Jowett.net as they might help somebody, somewhere, sometime.

Chris

I'd be really interested if someone with a similar engine can measure their pressure too?

I have so many photos. I need to know how to load them onto Jowett.net as they might help somebody, somewhere, sometime.

Chris

-

Keith Clements

- websitedesign

- Posts: 3968

- Joined: Wed Feb 08, 2006 11:22 am

- Your interest in the forum: Jup NKD 258, the most widely travelled , raced and rallied Jowett.

- Given Name: Keith

- Contact:

Re: Trying to narrow down oil leaks

I was surprised to read the Wikipedia entry on crankcase ventilation where it said that the Positive Crankcase Ventilation System was 'invented' (for cars) in 1952. Even more surprised to read here that most cars prior to 1963 vented to the atmosphere.

The Javelin was fitted with a pintel valve inserted in a pipe coming from the oil filler tube and going to the balance pipe that is part of the inlet manifold and thus subject to negative pressure when the engine is running (except when the throttle is wide open). I should think you could fit a similar pipe from the oil filler to a tapping into the pre-war inlet manifold and use a Javelin (or more modern) pintel valve.

Another possibility is to connect a tube from the oil filler pipe to the air filter (carburettor intake) where the draft of the intake air would suck in the crankcase gases. This would not be as good as the pintel valve as there is less control on the pressure but you could set it up so that it gave the right suck at cruising speeds and thus reduce oil leaks.

The reason your engine is so bad could simply be the bores and rings are worn thus creating too much crankcase pressure.

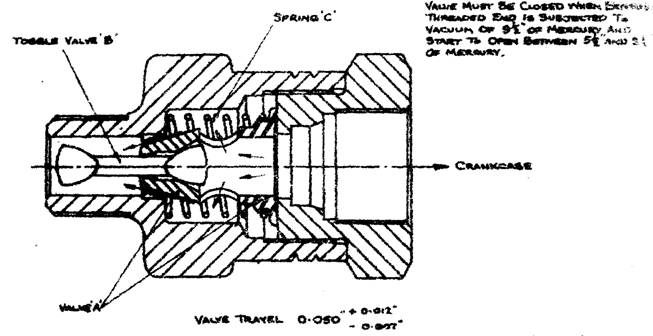

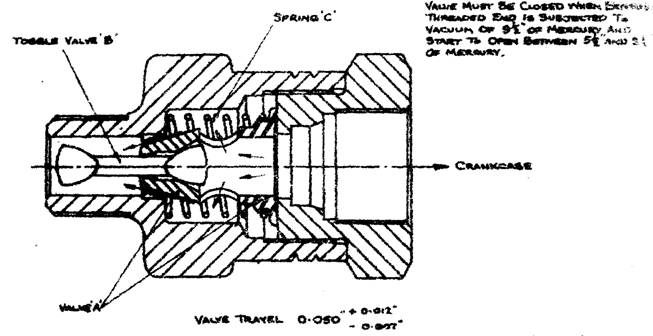

FROM: Tech Notes

Bulletin Issue Date: November 1953

Item No. 167. Crankcase Breather Valve – Javelin and Jupiter

To assist with the many enquiries regarding the crankcase breather valve, the following details are issued.

The crankcases of both the Javelin and the Jupiter are designed to operate at a pressure slightly below atmospheric pressure (14.7 psi), the normal running pressure in the crankcase being between 14 – 14.6 psi. To ensure even running of the twin carburettors a balance pipe was fitted from which runs a connecting pipe to the oil filler tube where the breather valve is located. To further assist the circulation of the air, breather vents are fitted one in each push rod cover, inside which, is tucked a small felt to act as an air filter. (Refer to Bulletin Item 9)

It is advisable to note the necessity of keeping the felts clean, as neglect of this point may cause failure of the petrol pump (Javelin) and bad engine performance.

When the engine is on tick-over or closed throttle, the pressure in the crankcase is 14 – 14.6 psi whilst in the balance pipe the pressure is approximately 8 – 10 lbs per square inch, and in this circumstance the breather valve is closed with the exception of the small airflow, which is consistent through the small toggle valve B, Figure 1.

If the breather valve was not closed and a free passage of air allowed from the crankcase to the balance pipe, the slow running mixture would be varied resulting in rough tick-over, engine hunting, excessive petrol consumption and flat spots on the initial take off.

It is therefore essential that the breather valve is closed on the tick-over or closed throttle. See Figure 1.

Valve must be closed when breather threaded end (connected to balance pipe) is subjected to 9½" of mercury and start to open between 5½" and 3½" of mercury.

Use conversion from https://www.metric-conversions.org/pres ... -water.htm as mercury is not that common these days but you will need a long pipe!

The Javelin was fitted with a pintel valve inserted in a pipe coming from the oil filler tube and going to the balance pipe that is part of the inlet manifold and thus subject to negative pressure when the engine is running (except when the throttle is wide open). I should think you could fit a similar pipe from the oil filler to a tapping into the pre-war inlet manifold and use a Javelin (or more modern) pintel valve.

Another possibility is to connect a tube from the oil filler pipe to the air filter (carburettor intake) where the draft of the intake air would suck in the crankcase gases. This would not be as good as the pintel valve as there is less control on the pressure but you could set it up so that it gave the right suck at cruising speeds and thus reduce oil leaks.

The reason your engine is so bad could simply be the bores and rings are worn thus creating too much crankcase pressure.

FROM: Tech Notes

Bulletin Issue Date: November 1953

Item No. 167. Crankcase Breather Valve – Javelin and Jupiter

To assist with the many enquiries regarding the crankcase breather valve, the following details are issued.

The crankcases of both the Javelin and the Jupiter are designed to operate at a pressure slightly below atmospheric pressure (14.7 psi), the normal running pressure in the crankcase being between 14 – 14.6 psi. To ensure even running of the twin carburettors a balance pipe was fitted from which runs a connecting pipe to the oil filler tube where the breather valve is located. To further assist the circulation of the air, breather vents are fitted one in each push rod cover, inside which, is tucked a small felt to act as an air filter. (Refer to Bulletin Item 9)

It is advisable to note the necessity of keeping the felts clean, as neglect of this point may cause failure of the petrol pump (Javelin) and bad engine performance.

When the engine is on tick-over or closed throttle, the pressure in the crankcase is 14 – 14.6 psi whilst in the balance pipe the pressure is approximately 8 – 10 lbs per square inch, and in this circumstance the breather valve is closed with the exception of the small airflow, which is consistent through the small toggle valve B, Figure 1.

If the breather valve was not closed and a free passage of air allowed from the crankcase to the balance pipe, the slow running mixture would be varied resulting in rough tick-over, engine hunting, excessive petrol consumption and flat spots on the initial take off.

It is therefore essential that the breather valve is closed on the tick-over or closed throttle. See Figure 1.

Valve must be closed when breather threaded end (connected to balance pipe) is subjected to 9½" of mercury and start to open between 5½" and 3½" of mercury.

Use conversion from https://www.metric-conversions.org/pres ... -water.htm as mercury is not that common these days but you will need a long pipe!

skype = keithaclements ;

-

ChrisE

- Posts: 82

- Joined: Sat Sep 01, 2018 8:23 am

- Your interest in the forum: Have a 1929 Full Four

- Given Name: Chris

Re: Trying to narrow down oil leaks

So Keith, are you thinking that the rings/bores are badly worn and I should look at getting that fixed (by a proper mechanic)? When I took out a plug, the other day, to turn the engine over, I could see that there was a teaspoon of engine oil in the bore of the piston, pushed into view when I hand turned the engine over to watch the piston go in-out.

Chris

Chris

-

Keith Clements

- websitedesign

- Posts: 3968

- Joined: Wed Feb 08, 2006 11:22 am

- Your interest in the forum: Jup NKD 258, the most widely travelled , raced and rallied Jowett.

- Given Name: Keith

- Contact:

Re: Trying to narrow down oil leaks

There are many ways to prove worn bores. Compression test. Leak test. Inspection with endoscope. Measuring. If you cannot do it yourself then take it to a prewar mechanic.

Those more conversant with the prewar will no doubt give some advice.

You could see how much compression there is when you turn it over by hand and also listen to see where the air is escaping when you turn it over. But a proper check is best. Iil on the plugs is a symptom as well.

Those more conversant with the prewar will no doubt give some advice.

You could see how much compression there is when you turn it over by hand and also listen to see where the air is escaping when you turn it over. But a proper check is best. Iil on the plugs is a symptom as well.

skype = keithaclements ;

-

Tony Fearn

- Posts: 1743

- Joined: Thu Feb 09, 2006 5:33 pm

- Your interest in the forum: Early pre-wars. Owner of 1933 'Flying Fox' 'Sarah Jane, and 1934 Short saloon 'Mary Ellen'.

- Given Name: Anthony

- Location: Clayton le Moors, Lancashire, the Premier County in the British Isles!!

Re: Trying to narrow down oil leaks

Chris, I have sent you a PM.

Tony.

Tony.

-

ChrisE

- Posts: 82

- Joined: Sat Sep 01, 2018 8:23 am

- Your interest in the forum: Have a 1929 Full Four

- Given Name: Chris

Re: Trying to narrow down oil leaks

Thank you Tony. Read the PM, I will try that.