Bradford Front Bearing Adjustment?

-

Keith Andrews

- Posts: 941

- Joined: Wed Jul 26, 2006 8:11 am

- Location: New Zealand

- Contact:

Bradford Front Bearing Adjustment?

With the bearing housing removed....

The rear has a retainer that holds the rear bearing in...

How tight does this need to be done up?

There is a cone spacer that fits between the inner race of the inner and outer bearing...should this be a little loose to prevent side loading of the bearings?

Also, how do the wheel studs come out? I see there is a thread, does the rear flated section need to be ground off?

And replacing with new studs, how is that done?

The rear has a retainer that holds the rear bearing in...

How tight does this need to be done up?

There is a cone spacer that fits between the inner race of the inner and outer bearing...should this be a little loose to prevent side loading of the bearings?

Also, how do the wheel studs come out? I see there is a thread, does the rear flated section need to be ground off?

And replacing with new studs, how is that done?

My Spelling is Not Incorrect...It's 'Creative'

-

Keith Andrews

- Posts: 941

- Joined: Wed Jul 26, 2006 8:11 am

- Location: New Zealand

- Contact:

-

Leo Bolter

- Posts: 367

- Joined: Sat Feb 10, 2007 10:32 am

- Your interest in the forum: Proud owner of:

1 x 1951 Jowett Jupiter

1 x 1952 LE Velocette

1 x 1952 Jowett Bradford

2 x 1982 Princess 2 litre - Location: R. D. 2, Palmerston North, 4472, New Zealand.

Gidday Keith,

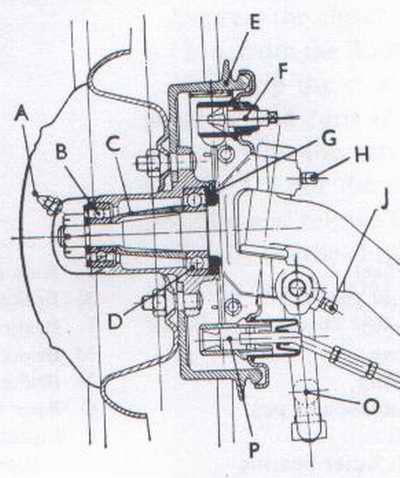

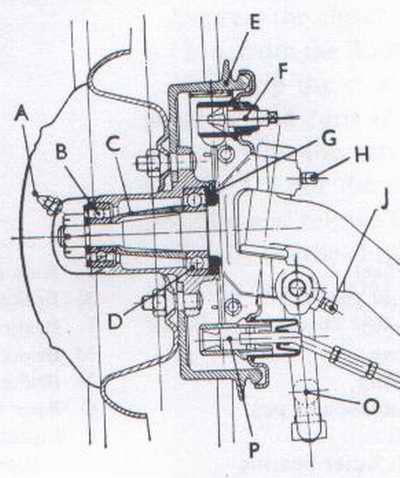

Looking up my manuals here, and assuming the Bradford you are working on has the same simple configuration shown in the diagram below, as far as the hub bearings go, this is the way I understand the setting up should be done.

First check a couple of dimensions.

The dimension "A" should be noted and compared with the length dimension of spacer "B". They should be the same.

Now lay a straight edge across each of the bearings so as to check that one bearing race (inner and outer) is not higher than the other (check both sides of each bearing). If not different all is ready to proceed with assembly.

If there is a discrepancy, either in the difference between A and B or the bearings, then that amount will have to be allowed for in assembly by making and fitting appropriate shims.

The object is to have no difference between the inner and outer races of the bearings causing "preloading" when the axle nut is done up tight.

I'm sure it probably goes without saying that the nut should NOT be slackened to achieve no pre-loading!!! . . . even though it has a split pin through the axle and nut!

This method of mounting the bearings does appear to be a bit crude as it doesn't seem to allow for expansion of one component with heat . . . but on thinking more about it, it is inevitable that the greatest heat will be in the brake drum/hub and as such it'll open up the dimension A and so not cause pinching of the bearings.

Well, that's my theory anyway! ':)'

Looking up my manuals here, and assuming the Bradford you are working on has the same simple configuration shown in the diagram below, as far as the hub bearings go, this is the way I understand the setting up should be done.

First check a couple of dimensions.

The dimension "A" should be noted and compared with the length dimension of spacer "B". They should be the same.

Now lay a straight edge across each of the bearings so as to check that one bearing race (inner and outer) is not higher than the other (check both sides of each bearing). If not different all is ready to proceed with assembly.

If there is a discrepancy, either in the difference between A and B or the bearings, then that amount will have to be allowed for in assembly by making and fitting appropriate shims.

The object is to have no difference between the inner and outer races of the bearings causing "preloading" when the axle nut is done up tight.

I'm sure it probably goes without saying that the nut should NOT be slackened to achieve no pre-loading!!! . . . even though it has a split pin through the axle and nut!

This method of mounting the bearings does appear to be a bit crude as it doesn't seem to allow for expansion of one component with heat . . . but on thinking more about it, it is inevitable that the greatest heat will be in the brake drum/hub and as such it'll open up the dimension A and so not cause pinching of the bearings.

Well, that's my theory anyway! ':)'

Last edited by Leo Bolter on Fri Aug 17, 2007 12:48 am, edited 2 times in total.

R. Leo Bolter,

Palmerston North,

New Zealand.

JCC of NZ - Member No 0741.

JOAC - Member No 0161

Car: Jupiter (E1-SA-513-R)

Skype name = jupiter1951

Messenger name = r.l.bolter"at"massey.ac.nz

Palmerston North,

New Zealand.

JCC of NZ - Member No 0741.

JOAC - Member No 0161

Car: Jupiter (E1-SA-513-R)

Skype name = jupiter1951

Messenger name = r.l.bolter"at"massey.ac.nz

-

Keith Andrews

- Posts: 941

- Joined: Wed Jul 26, 2006 8:11 am

- Location: New Zealand

- Contact:

This is a pic from a bradford manual I have here, and is the same as all the hubs I have

The outter bearing B is pressed in

The Cone C ...it is not a machined peice to length and none of the hubs have shims at all....drops in from the back

The cone holds against the inner race of both bearings.

The inner bearing D is then dropped in and sits against the cone.

Then the ring G then screws into the back of the hub...this is machined to tighten up against the outter race of the rear bearing.

Behind this is a felt grease/dust seal.

The Castle nut washer is machined to tighten up against the inner race of the outter bearing...

Im getting myself messed up with logic...

When the castle nut is tightened it puts pressure on the outter bearing inner race, thru the cone to the inner bearing inner race???

Therefore it should follow (???) that if the rear ring G is tightened till there is no play, but not too tight, and the castle nut , the same, assuming the outter bearing is known to be pressed fully in.....

That right?

Also how to replace wheel studs?

The outter bearing B is pressed in

The Cone C ...it is not a machined peice to length and none of the hubs have shims at all....drops in from the back

The cone holds against the inner race of both bearings.

The inner bearing D is then dropped in and sits against the cone.

Then the ring G then screws into the back of the hub...this is machined to tighten up against the outter race of the rear bearing.

Behind this is a felt grease/dust seal.

The Castle nut washer is machined to tighten up against the inner race of the outter bearing...

Im getting myself messed up with logic...

When the castle nut is tightened it puts pressure on the outter bearing inner race, thru the cone to the inner bearing inner race???

Therefore it should follow (???) that if the rear ring G is tightened till there is no play, but not too tight, and the castle nut , the same, assuming the outter bearing is known to be pressed fully in.....

That right?

Also how to replace wheel studs?

My Spelling is Not Incorrect...It's 'Creative'

-

Leo Bolter

- Posts: 367

- Joined: Sat Feb 10, 2007 10:32 am

- Your interest in the forum: Proud owner of:

1 x 1951 Jowett Jupiter

1 x 1952 LE Velocette

1 x 1952 Jowett Bradford

2 x 1982 Princess 2 litre - Location: R. D. 2, Palmerston North, 4472, New Zealand.

Keith.

The way I see it, using your illustration . . . . (which is basically the same as mine . . . it is of a hub found in a very early Javelin workshop manual, incidentally).

If the outside bearing (B) is pressed in as far as the land/flange in the hub will allow and the inner one (D) also held against it’s hub land by the screwed ring (G) and we consider this as being a set distance, then the length of the inner cone spacer (C) has to be organized to be that same set distance, so that when the castellated nut is tight there’s no possibility of “crushingâ€

The way I see it, using your illustration . . . . (which is basically the same as mine . . . it is of a hub found in a very early Javelin workshop manual, incidentally).

If the outside bearing (B) is pressed in as far as the land/flange in the hub will allow and the inner one (D) also held against it’s hub land by the screwed ring (G) and we consider this as being a set distance, then the length of the inner cone spacer (C) has to be organized to be that same set distance, so that when the castellated nut is tight there’s no possibility of “crushingâ€

Last edited by Leo Bolter on Sat Jun 23, 2007 12:59 pm, edited 4 times in total.

R. Leo Bolter,

Palmerston North,

New Zealand.

JCC of NZ - Member No 0741.

JOAC - Member No 0161

Car: Jupiter (E1-SA-513-R)

Skype name = jupiter1951

Messenger name = r.l.bolter"at"massey.ac.nz

Palmerston North,

New Zealand.

JCC of NZ - Member No 0741.

JOAC - Member No 0161

Car: Jupiter (E1-SA-513-R)

Skype name = jupiter1951

Messenger name = r.l.bolter"at"massey.ac.nz

-

Bryan Walker

- Posts: 114

- Joined: Fri Feb 10, 2006 9:33 am

- Your interest in the forum: Jowett owner

- Given Name: Bryan

- Location: New Zealand

-

Keith Andrews

- Posts: 941

- Joined: Wed Jul 26, 2006 8:11 am

- Location: New Zealand

- Contact:

Thanks Leo

Therefore the rear should be able to be ground or drilled out, then screwed out....

A new one should be able to be screwed in, welded? or a nut used and touch lock welded on the end ?

Simply welded to the back, seems to me to be a clumbsy option, and putting that sort of heat into a hub component? that a bit suspect to me.

The nut locktited or even spot locked far better?

Yes that is correct....but they are not pressed in, they are screwed in then expanded....I don't think you can replace an individual stud (pressed in from thread end and the the other end was then expanded / pressed).

Therefore the rear should be able to be ground or drilled out, then screwed out....

A new one should be able to be screwed in, welded? or a nut used and touch lock welded on the end ?

Simply welded to the back, seems to me to be a clumbsy option, and putting that sort of heat into a hub component? that a bit suspect to me.

The nut locktited or even spot locked far better?

My Spelling is Not Incorrect...It's 'Creative'

-

Keith Clements

- websitedesign

- Posts: 3968

- Joined: Wed Feb 08, 2006 11:22 am

- Your interest in the forum: Jup NKD 258, the most widely travelled , raced and rallied Jowett.

- Given Name: Keith

- Contact:

-

Keith Andrews

- Posts: 941

- Joined: Wed Jul 26, 2006 8:11 am

- Location: New Zealand

- Contact:

-

Keith Andrews

- Posts: 941

- Joined: Wed Jul 26, 2006 8:11 am

- Location: New Zealand

- Contact:

The cost for a sett of Wheel studs is not much less than a new hub +bearing assembly from Jowett Spares NZ

We have laid out all the parts, with a quailfied mechanic very well experianced in old engish cars

!/The cone is dropped in from the rear.

2/ The rear bearing is pressed in 1st and the screw in bearing holder knicked up tight.

3/the outter bearing is then pressed in with the cone lined up...do not press home, otherwise the inner races are loaded.

4/ The rear seal, hub put on the stub axle, the special macined washer put on so it loads the inner bearing race, and then finally seated with the axle nut. Do not over tighten...back off a little lock with split pin. Recheck after a good run.

The inner race of the rear bearing sits against a lip on the axle, the cone spaces both inner races, which are loaded with the machined washers and axle nut...

The outter race of the outter bearing doesnt sit fully seated in the hub.

A bit of a mickey house (primative) setup

Bearings, the inner hub between the cone and hub are all packed with grease as it is assembled.

We have laid out all the parts, with a quailfied mechanic very well experianced in old engish cars

!/The cone is dropped in from the rear.

2/ The rear bearing is pressed in 1st and the screw in bearing holder knicked up tight.

3/the outter bearing is then pressed in with the cone lined up...do not press home, otherwise the inner races are loaded.

4/ The rear seal, hub put on the stub axle, the special macined washer put on so it loads the inner bearing race, and then finally seated with the axle nut. Do not over tighten...back off a little lock with split pin. Recheck after a good run.

The inner race of the rear bearing sits against a lip on the axle, the cone spaces both inner races, which are loaded with the machined washers and axle nut...

The outter race of the outter bearing doesnt sit fully seated in the hub.

A bit of a mickey house (primative) setup

Bearings, the inner hub between the cone and hub are all packed with grease as it is assembled.

My Spelling is Not Incorrect...It's 'Creative'